Mistakes to Avoid in the Storage Industry

Eight Mistakes in the Storage Industry

- Keeping a Professional Warehouse Facility

- Keep an Eye Out While Employees Do Inventory Management

- Being Lazy is the Biggest Mistake

- How the Layout of a Storage Warehouse Can Be Influential

- Warehouse Management Technology

- Warehouse Management Automation Improves Accuracy

- Finding Areas of Improvement for a Storage Warehouse

- Moving Authority Resources For Moving & Storage Industry

1. Keeping a Professional Warehouse Facility

How do professional storage or warehouse facilities maintain all the specific requirements involved to keep it professional as well as accommodating? It can't be an easy task to run or manage one of these massive areas of space, let along keep everything in place, clean, and organized. That must take some serious logistical management. As one can imagine, it seems like it would be easy to make mistakes in the storage industry, just like it happens in the moving industry as well. People often tend to overlook problems that are rather common but result in a drop of productivity and increase costs. So what kind of mistakes do you want to make sure you don't make if you ever find yourself working for or owning a professional storage facility/warehouse in the moving and storage industry.2. Keep an Eye Out While Employees Do Inventory Management

This is an obvious no, no - without enough space to fit the inventory that you've agreed to store in your warehouse can lead to customer complaints, bad reviews, and customer dissatisfaction. Not to mention have to deal with management problems on top of it all. The mistake is that when you don't have an accurate inventory list or it got lost, the whole warehouse team is left running in circles to find what's missing. This leads into another issue of productivity. When you have inventory that is minute or kind of pointless to count or move, the warehouse management is usually who customers see fit to blame for discrepancies or lost items. This is rather unfortunate for management because it really isn't their fault, but the fault of their inventory team. Although, if this is a continuous problem for your facility, an assessment of employee productivity and efficiency should be done to address this kind of issue.3. Being Lazy is the Biggest Mistake

Warehouse employees sometimes avoid taken the hard road aka the physical inventories or performing the cycle counts because they believe it's just a waste of time and they don't really need to go through the painful process. To be frank, this is unfortunate for management and especially customers who have inventory in the storage warehouse. No matter how accurate your inventory records are, the consistent cycle of counts should never be done to cover up an error. Especially if you could remedy the situation by correcting the count. It should be required for warehouse employee teams to undergo investigations in regards to the accuracy of their inventory counts. Surely this would shed some light on issues within the warehouse, particularly those in regards to procedures that are put into place to improve warehouse inventory and the accuracy of it. If you find that something may be missing from your inventory list, go directly to management with the understanding that they didn't do this, their warehouse team likely made the mistake.4. How the Layout of a Storage Warehouse Can Be Influential

In the moving and storage industry, there is always developing ways to avoid scams and low-cost moving companies because they may be rogue movers. But the tables turn when speaking about the storage industry in itself. Typically, scams or rogue movers, etc. say they are cheap, give you discounts, and many just flat out lie. In the storage industry, when there is a new owner of a warehouse or facility, if they make no changes at all, they're either strapped for cash, too cheap to upgrade the facility, or they don't see a need to.This doesn't mean every single individual owner needs to redesign their warehouse, but if you can create a space for a better, more efficient type of layout without having to go all out, why wouldn't you? At some point, management will need to evaluate and assess the productivity of their warehouse, the layout, and their warehouse team.

This is especially true when it comes to the nitty gritty details of the warehouse itself and the policies etc. Such as if it will be long term, short term, or both. Then the rates should be determined along with what they will and won't accept, how they will keep their belongings or goods, what kind of special features it has, and it keeps going. All of these details will need to be assessed as well.

5. Warehouse Management Technology

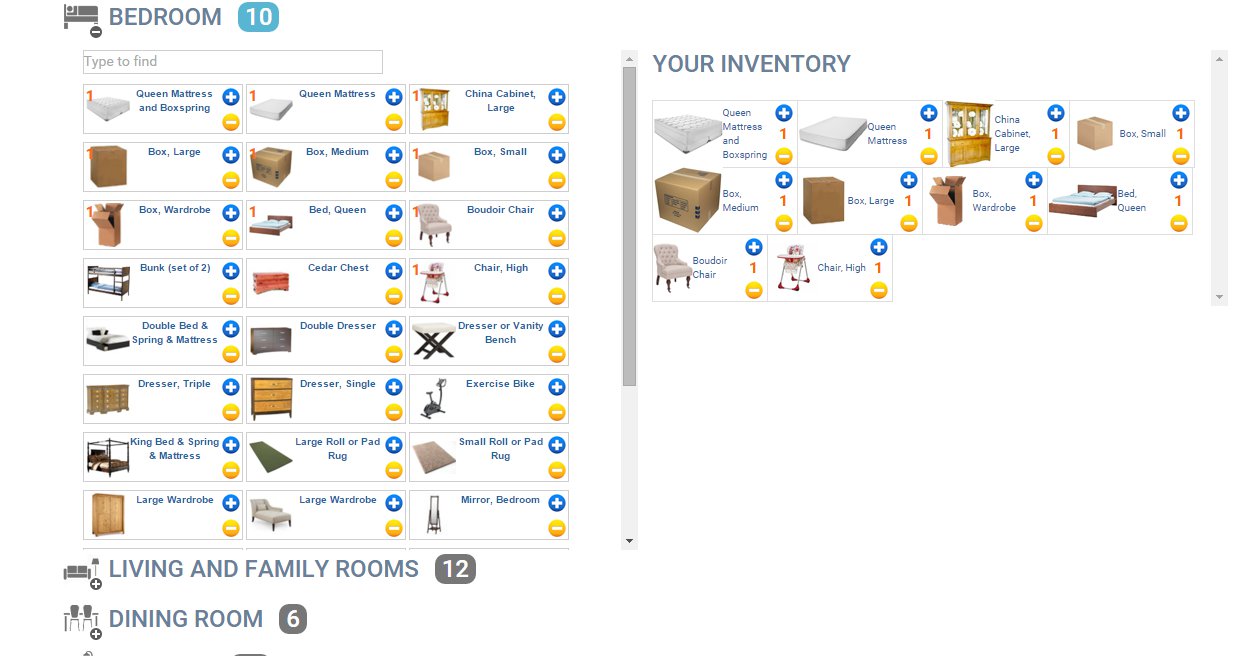

In the moving and storage industry, warehouses have a specific warehouse execution software (WES) solution. Without any experience in this field, this will not be a huge focal point, yet it is important to acknowledge because it is allowing the storage industry to be much more efficient in more ways than one. It's a software that is said to increase keeping track of inventory locations and is a way to go green, another benefit as our world continues to heat up. Some claim that without this program, their warehouse management and productivity would take a pretty steep dive while your costs spike up. It is definitely something for the professionals either with or without a moving company to look into.6. Warehouse Management Automation Improves Accuracy

Unfortunately, it seems like everything is automated today, particularly on the phone (which is most annoying). Automation is all around us in all industries, both domestically and internationally. We're now living in a cyber world that is still developing with social media and all the platforms that exist for consumers as well as those that are for marketers.However, it's especially important to use some kind of warehouse automation i.e bar coding equipment or storage retrieval systems. Many warehouse managements will express the benefits of automating warehouse software. Essentially every company can benefit from this, most importantly in the way in which automated storage and retrieval solutions work. They allow for a much larger volume of material with a much smaller impact. Thus, this increases productivity, getting rid of unnecessary time and improve inventory accuracy. It keeps the warehouse team on their toes to be blunt. Like any software or technological development, it's important to remember that even machines make mistakes too sometimes.

7. Finding Areas of Improvement for a Storage Warehouse

Similar to problems during the moving process, there are also negative factors that impact the storage industry as well. It's important to recognize where improvements can be made, but it's even better to know beforehand what mistakes you don't want to make if you're buying, renting, or a customer storing your goods. Professional moving companies that are reputable and trustworthy, are typically interstate or long-distance, but they generally offer high-quality storage facilities that are climate-controlled with high security.8. Moving Authority Resources For Moving & Storage Industry

As always, Moving Authority has lists and lists of moving companies, moving companies with storage, and simply storage focused facilities. With our resources, you should be able to find a good mover or storage warehouse.Protect yourself from scams, that yes, happen even in the storage industry alone. Not everyone is a bad apple, you just need proper advice and tools to separate them.

Add Comment